Industries We Serve

Steelhead Composites supports a wide range of industrial and research applications, providing safe, efficient, and compliant gas storage solutions for diverse environments.

- Advanced Manufacturing

- Energy & Power Systems

- Defense & Aerospace

- Laboratory & R&D Facilities

- Oil, Gas & Mining

- Food & Beverage Processing

- Environmental & Life Sciences

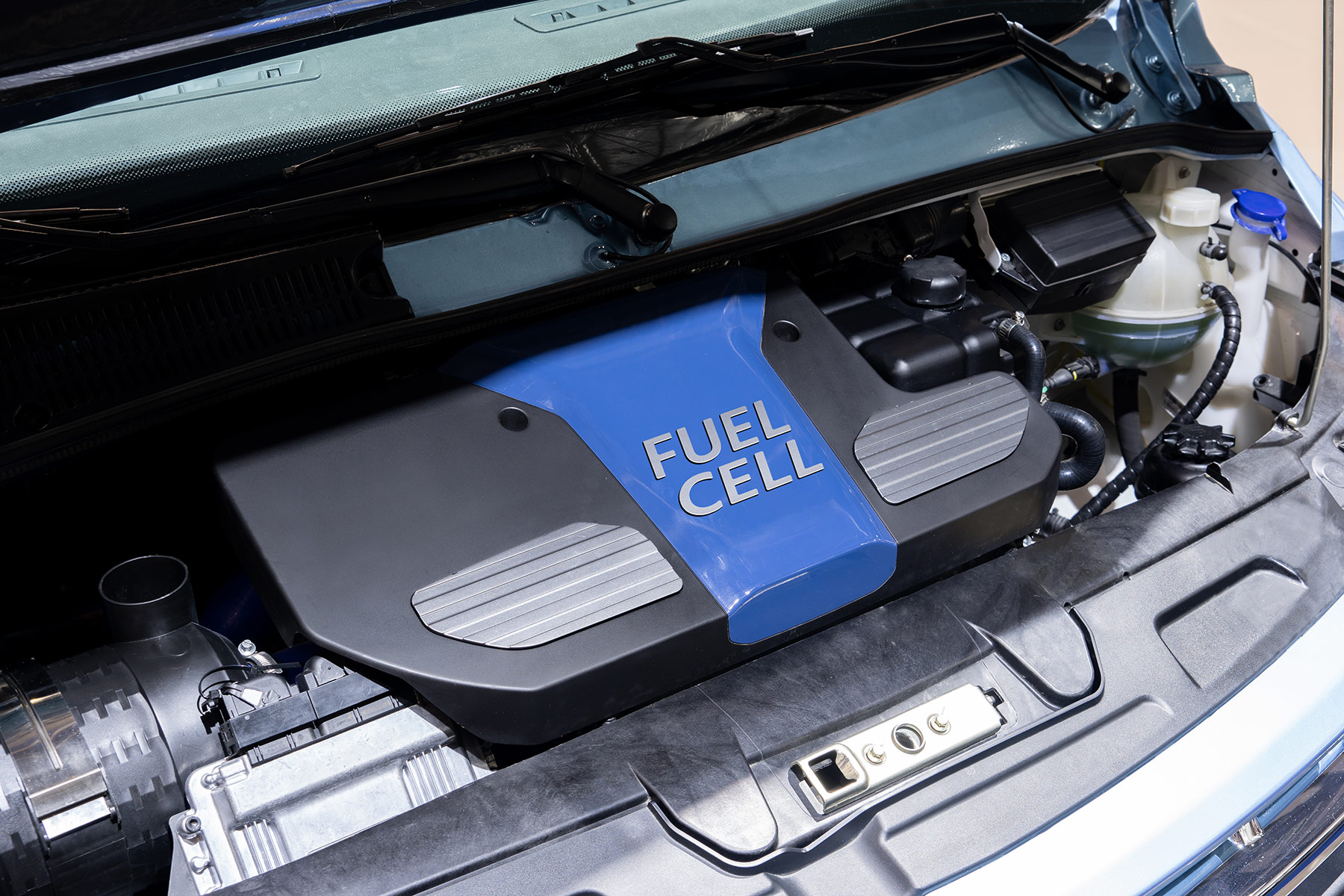

Industrial and research operations demand versatile, durable, and certified gas storage solutions. Steelhead Composites provides composite overwrapped pressure vessels (COPVs) engineered to safely store a wide variety of gases, including hydrogen, nitrogen, helium, and CO₂. Our vessels are designed for stationary, mobile, and lab-scale use, offering corrosion resistance, long service life, and compatibility with extreme operating environments.

From ground storage to trailer-mounted transport systems, Steelhead delivers scalable solutions tailored to customer needs. With ASME, ISO, CE, and DOT certifications, we ensure compliance across global deployments. Whether supporting industrial manufacturing, environmental control, or cutting-edge hydrogen R&D, Steelhead enables safe, efficient, and future-ready operations.

Challenges

Solutions and Recommendations

Steelhead provides high-capacity composite pressure vessels engineered specifically for fixed installations—whether for industrial gas storage, energy buffering systems, or laboratory environments. Our vessels deliver long service life, low maintenance requirements, and reliable performance across a broad range of gases and operating pressures. This makes them an excellent choice for permanent infrastructure as well as precision-driven research applications.

Steelhead delivers mobile composite storage systems designed for reliable transport of gases between facilities or out to remote worksites. Our skid-mounted and trailer-integrated vessels provide safe handling, high payload efficiency, and rapid deployment in the field—ideal for industries such as oil and gas, mining, mobile fueling, and remote research operations.

Steelhead provides full-spectrum testing and certification services—including hydrostatic, burst, fatigue, and environmental validation—to confirm vessel performance under demanding operational conditions. Our processes support compliance with stringent domestic and international regulations, ensuring each system is fully qualified for deployment in highly regulated, mission-critical, and global applications.

Relevant Projects

Defense breathing air systems, hydrogen generation & deployment systems

Steelhead’s vessels are used in military-grade breathing air systems and hydrogen generation platforms, where reliability, portability, and safety are paramount. These systems support field operations, mobile energy units, and mission-critical logistics.

Industrial gas storage for carbon dioxide, buffer air storage, nitrogen, helium storage and systems

Our COPVs are deployed in industrial facilities for the storage and regulation of various gases used in manufacturing, food processing, and environmental control. Their lightweight design and corrosion resistance make them ideal for both indoor and outdoor installations.

R&D hydrogen testing skids

Steelhead supports research institutions and technology developers with custom hydrogen storage solutions integrated into test skids. These systems enable safe experimentation with fuel cells, electrolyzers, and hydrogen combustion technologies—accelerating innovation in clean energy and propulsion.