Verification Through Testing

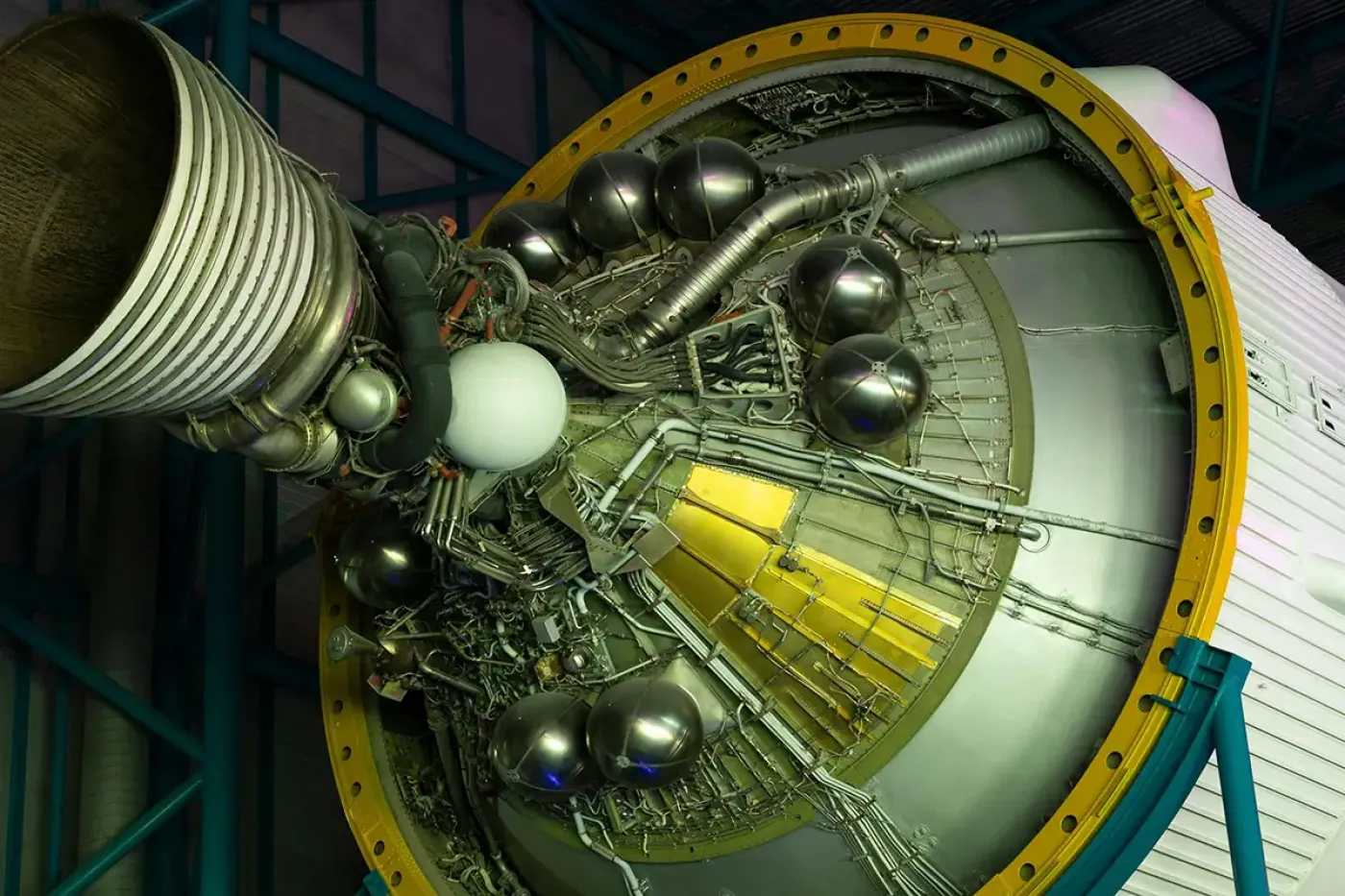

Steelhead Composites has earned flight and field heritage across a wide range of Aerospace, Space, and Defense (ASD) platforms—including vessels qualified under S-080, S-081, and multiple MIL-SPEC standards. Achieving this level of trust and certification requires rigorous, repeatable testing. That’s why we offer a comprehensive suite of in-house testing services tailored to the unique demands of ASD programs. Whether developing a next-generation propulsion system or qualifying a life-support tank for orbital use, Steelhead’s testing infrastructure and engineering expertise ensure a smooth path from prototype to flight-ready with confidence.

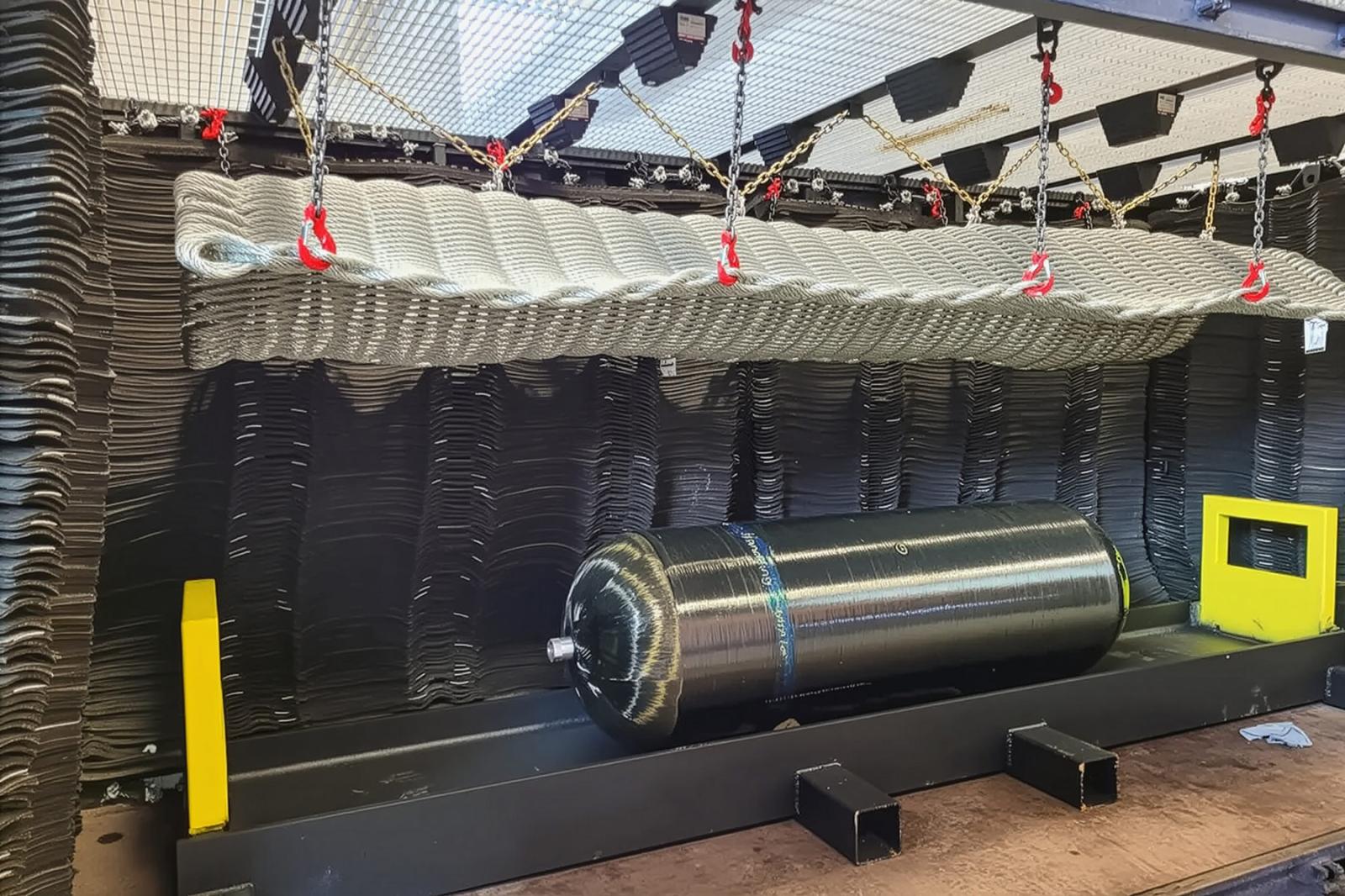

At Steelhead, we test every pressure vessel like lives depend on it—because they do.

Our in-house test lab performs a full range of qualification and validation protocols to ensure every vessel meets or exceeds the stringent requirements of aerospace and defense applications. Testing capabilities include:

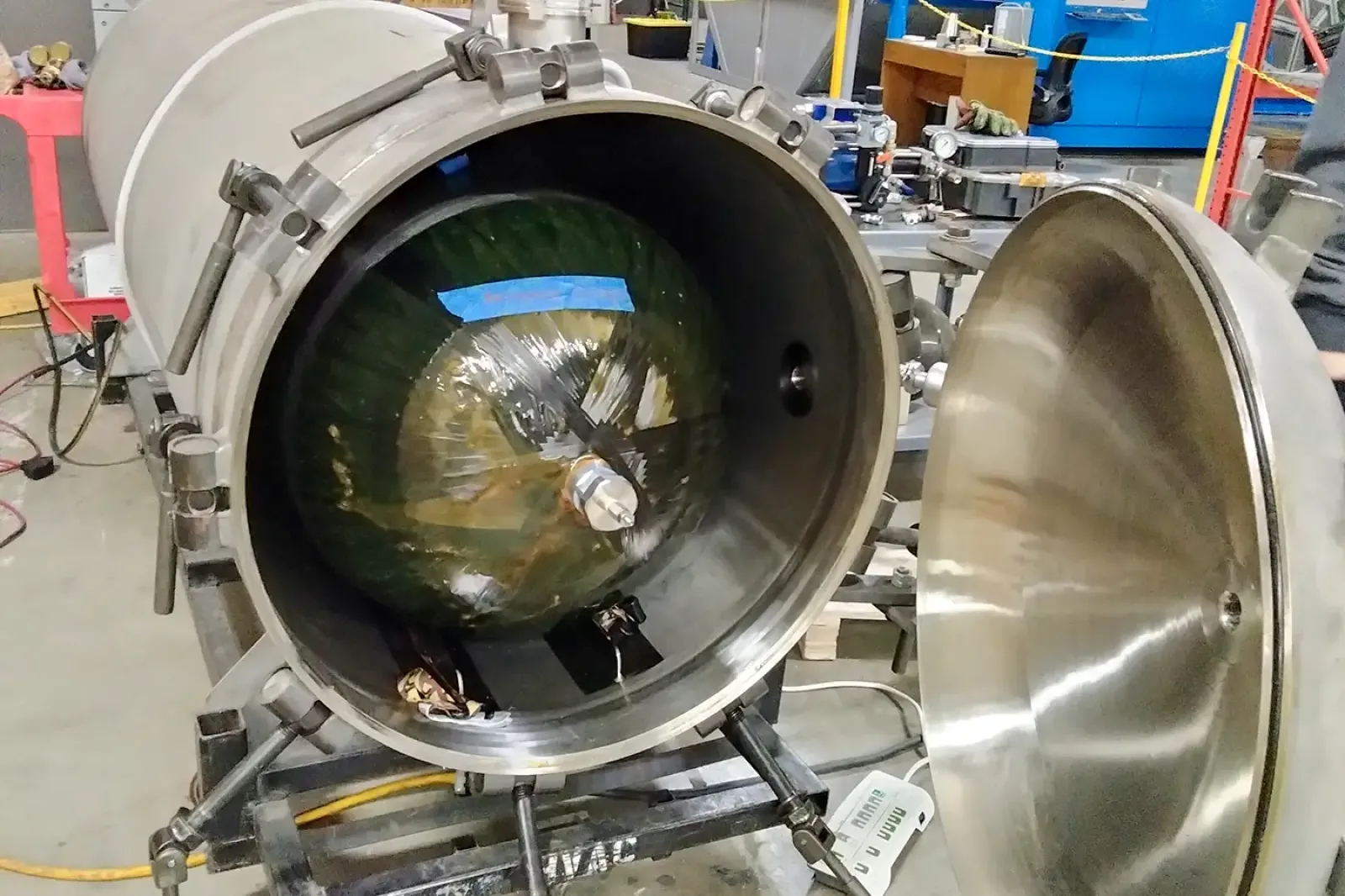

- Hydrostatic Burst Testing – Determines ultimate vessel strength and validates safety margins.

- Leak Testing – Uses helium mass spectrometry and pressure decay methods to confirm zero leakage in both operational and standby conditions.

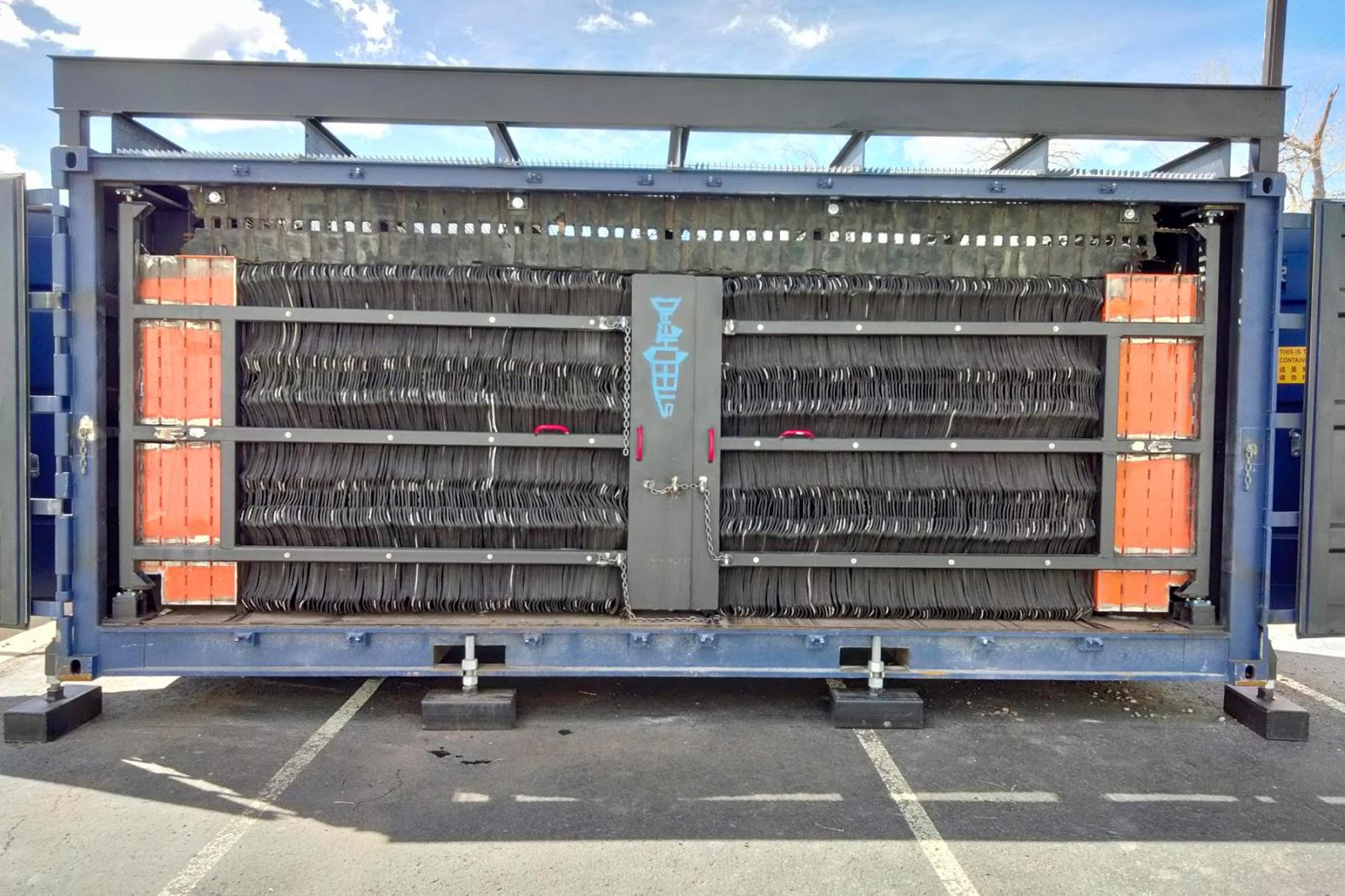

- Cycle Testing – Simulates thousands of pressure cycles to assess fatigue life and long-term reliability.

- Thermal Conditioning – Exposes vessels to extreme temperature ranges to verify performance in space, high-altitude, and battlefield environments.

- Dimensional & Structural Inspection – Ensures vessels meet precise tolerances for integration into complex aerospace assemblies.

Steelhead supports customers from early-stage R&D through final flight qualification. Our team collaborates closely with yours to define test plans, execute protocols, and deliver detailed documentation packages supporting certification with NASA, DoD, FAA, and commercial aerospace partners.

With decades of experience in composite pressure systems and a proven track record of successful flight programs, Steelhead is a trusted partner for pressure vessel validation in the most demanding environments.